Cut to Length Production Line

It is used for uncoiling, leveling, sizing, cutting and stacking metal coils into flat sheets of desired length. It is suitable for processing cold-rolled and hot-rolled carbon steel, silicon steel, tinplate, stainless steel and various metal materials after surface coating.

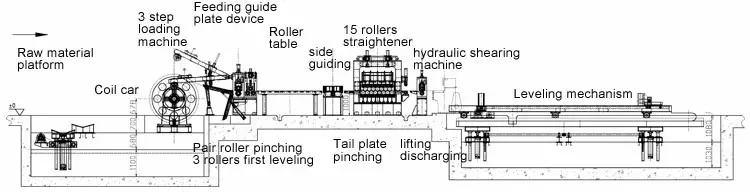

The production line is mainly composed of feeding trolley, uncoiler, leveling machine, feeding mechanism, shearing machine, conveying device, stacking device, etc. A slitting machine can be configured in the production line to cut the sheets into required widths, cut them to length and stack them. It is a high-performance product integrating machinery, electricity and hydraulics.

High degree of automation, simple and reliable operation.

High fixed-length precision and high sheet flatness.

The stacking is neat

Quick Details

|

Cutting Width (mm): |

500 - 2000 mm |

Material Thickness(mm): |

2 - 8 mm |

|

Cutting Speed(m/min): |

1 - 40 m/min |

Coil Weight (T): |

30T |

|

Leveling Precision(±mm/m): |

1.5 ±mm/m |

Voltage: |

380v |

|

Rated Power: |

300KW |

Dimension(L*W*H): |

28X8X2m |

|

Weight: |

5000 |

Coil Thickness: |

2-8mm |

|

Coil width: |

800-2000mm |

Coil weight: |

max 30T |

|

Total line power consumption: |

300KW |

Total weight: |

50T |

|

Line Speed: |

40m/min |

Cutting length: |

2000mm-12000mm |

|

Core Components: |

PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pu |

||

Video

Description&Function

1.What is Cut To Length Machine The Cut To Length Machine also called cut to length line which are used for uncoiling,leveling and cutting the metal coil into the required length of flat sheet material and stacking.It suitable for processing cold rolled and hot rolled steel, coil,galvanized steel coil,silicon steel coil, stainless steel coil,aluminum coils etc into different width according to the users production demands and cut as well

2.Function This equipment through the procedure of uncoiling, leveling, precision gauge cutting, processing the strip steel coil into required steel pate. It mainly composed of uncoiler, pincher and leveler, gauge, cutting machine , stacker, etc, with assists of feeder, side guiding device, transition, and conveyor, etc.

3.Category According to the metal materials there are stainless steel cut to length machine,silicone steel cut to length machine,cold or hot rolled plate cut to length machine and so on. According to its electronic control mode there are pneumatic cut to length line,NC cut to length line and etc.

|

Type |

3×1600 |

6×2000 |

8×2000 |

10×2200 |

12×2200 |

16×2200 |

20×2500 |

25×2500 |

|

Thickness Range(mm) |

0.3-3 |

1-6 |

2-8 |

2-10 |

3-12 |

4-16 |

6-20 |

8-25 |

|

Width Range(mm) |

1600 |

2000 |

2000 |

2200 |

2200 |

2200 |

2500 |

2500 |

|

Cutting Length(mm) |

300-4000 |

500-6000 |

600-8000 |

600-10000 |

800-12000 |

800-12000 |

800-12000 |

800-12000 |

|

Cutting precision(mm) |

±0.5 |

±0.5 |

±1 |

±1 |

±1 |

±1 |

±1 |

±1 |

|

Roller Numbers |

15 |

15 |

13 |

13 |

11 |

11 |

9 |

9 |

|

Roller Diameter(mm) |

Ф85 |

Ф140 |

Ф155 |

Ф160 |

Ф180 |

Ф200 |

Ф230 |

Ф260 |

|

Item |

specifications |

||

|

Raw materials |

Materials feature: |

HR YS 450 TS 350 |

|

|

thickness: |

2.0mm-8.0mm |

||

|

width: |

800mm-2000mm |

||

|

O.D: |

Φ1000mm-φ2150mm |

||

|

I.D: |

φ500mm-φ800mm |

||

|

Coil weight: |

Max 30T |

||

|

Finished product |

Cutting length: |

2000mm-12000mm |

|

|

Cutting tolerance: |

±1.5mm( length tolerance) ±2.0mm( diagonal tolerance) Match the standard GB/T709-88 |

||

|

Leveling speed |

0-40m/min |

||

|

Max cutting thickness |

12mm |

||

|

Center line of the line ( to the ground) |

800mm |

||

Standard Flow chart of cut to length machine

Coil lifter --- hydraulic decoiler --- snubber roller --- pinch roll & pre-leveler --- loop bridge --- side guide roller --- main leveling machine --- encode & measuring device (with tail plate pinching) --- shear --- conveyor --- hydraulic lift platform --- stacker with blower device --- unload cart

Packaging And Delivery

Exhibition Photos

Certificate

FAQs

Q: Are you manufacturer?

A: Yes,we are manufacturer.We have 2 factories and our own technical team.Welcome to visit us.

Q: What kind o f payment term you can do?

A: We can accept T/T and L/C.

Q: What info you need before you make the proposal?

A: The pipe diameter , thickness range , usage, raw material steel grade, coil weight and automatic degree.

Q: What should I do if I just start a new business?

A: Contact us immediately ,we provide free consultant for pre-sales service.Also we can help you to solve the raw material (steel coil) purchase,worker training,international market price.

Q: How do you do QA?

A: We have special team to do strict QA, this is one of our strengths:

(1) Every gear box will be tested for 8 hours with oil inside to guarantee there is no leak.

(2) Every shaft will be inspected for the centering jumpiness.

(3) Every roller will be checked to make sure its in the range of tolerance critical parts will be inspected for all dimensions.

Q: Why I should choose you,what are the differences between you and other Chinese suppliers?

A: We are concentrate on this industry for more than 20 years,and especially in pipe making machines. Our pipe making machine line directly export to Russia,Vietnam,India,Indonesia,and many other countries in Asia, Africa, middle east and South America.